Classification of crushers in mining machinery industry

2014-11-24

According to different requirment from different customers in mining or other industry, the leading manufacture make a general classification of crusher. And the classification is based on two features of crusher.

No.1 The size of raw materials crushed. All kinds of crushing machine is divided into: first crusher, the raw materials can be crushed from 1500-500mm into 350-100mm; secondary crusher, 350-100mm raw materials is crushed into 100-40mm; at last, fine crusher, the size of raw materials is from 100-40mm to 30-10mm.

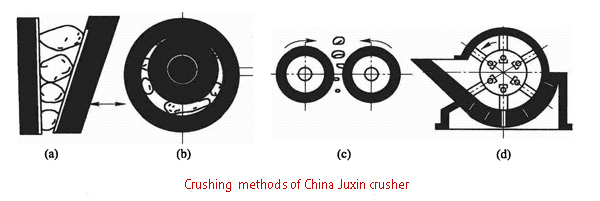

No.2 The working principle and architectural feature of crusher. According to these principle, mineral crusher has four types:

2) Cone crusher(b): two nearly concentric conicalnesses(one stable exterior conicalness, one movable inner conicalness ) are its main working parts. On the basis of the certain eccentric radius, inner conicalness is in eccentric motion around the exterior conicalness. At the same time, ore between two conicalnesses can be crushed by granulitization and broken.

3) Double roll crusher(c): Between the parallel rollers with motation in both directions, ore is crushed by granulitization(two smooth rollers), or by granulitization and cutting(two tooth rollers). When the revolution of two rollers is different, ore is also crushed by grinding.

4) Impact crusher(d): impacting crusher and hammer crusher: they mainly crush ore by two effects, one is the impacting effect of hammer with high rotating speed, other is the impacting effect when the raw materials goes close to the fixed liners.

.jpg)