How to choose the best shaft and bearing for jaw crusher

2014-12-17

When the jaw crusher is on, it has a strong impact strength, so based on the working feature of jaw crusher, China Juxin re-study and manufacture the shafts and bearings. The shaft and bearing of meduim and large jaw crusher use the materials of alloy steel and carbon steel, and the small jaw crusher use the shaft and bearing with the materials of 35-45# steel.

The radian of the sliding bearing has a great influence on the service life of jaw crusher. In general, for the meduim, lage jaw crusher, the shaft and bearing sften uses the materials of babbitt metal or the substitute material. The reason is that it can bear the strong impact force and very wear-resisting, but it has the lowest transmission efficiency and lubrication device is necessary. Compared with the sliding bearing, the antifriction bearing has the simnple structure and the short length, but it's low efficient and low resistance for the impact force, so it's just suitable for small type jaw crusher.

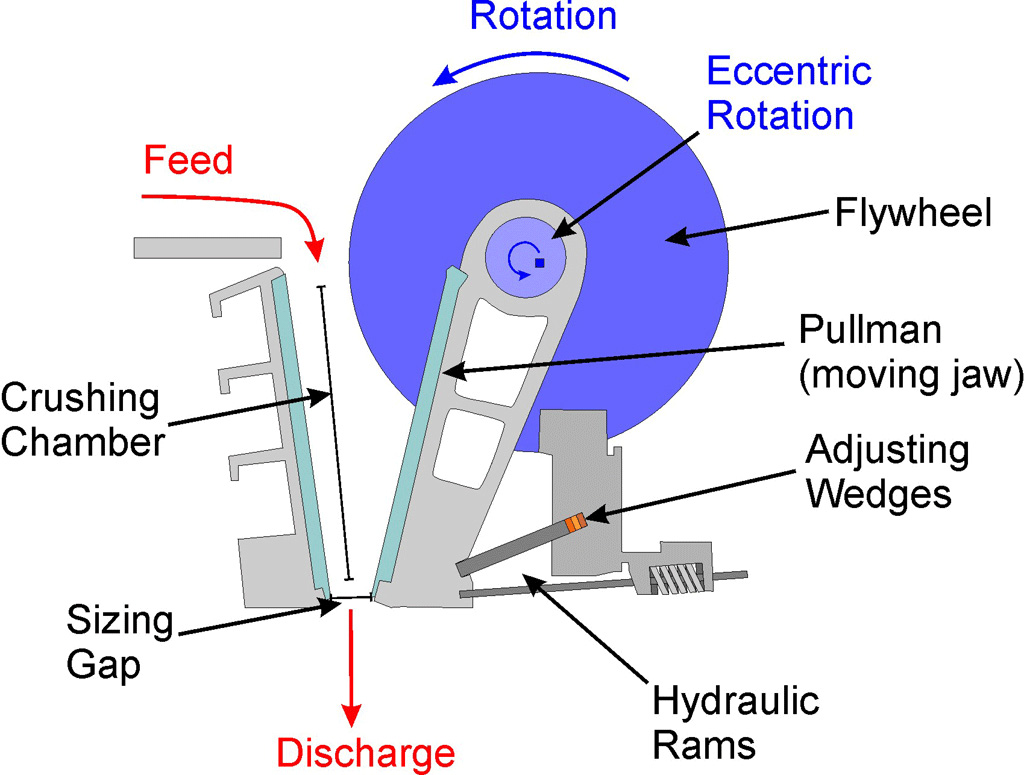

For the greatest benefit of customers, China Juxin offer a proposal that the combination of eccentric shaft and antifriction bearing has the best efficiency. In China Juxin, the combination of eccentric shaft and sliding bearing use the 3-level turn-fit seat, and the 2-level turn-fit seat is suitable for the combination of eccentric shaft and antifriction bearing.

.jpg)